Joint Calibrator

Robots can be precisely calibrated using the Petoi Desktop App.

Please go through to the introduction for installing the Petoi Desktop App and connecting the robot to your computer first

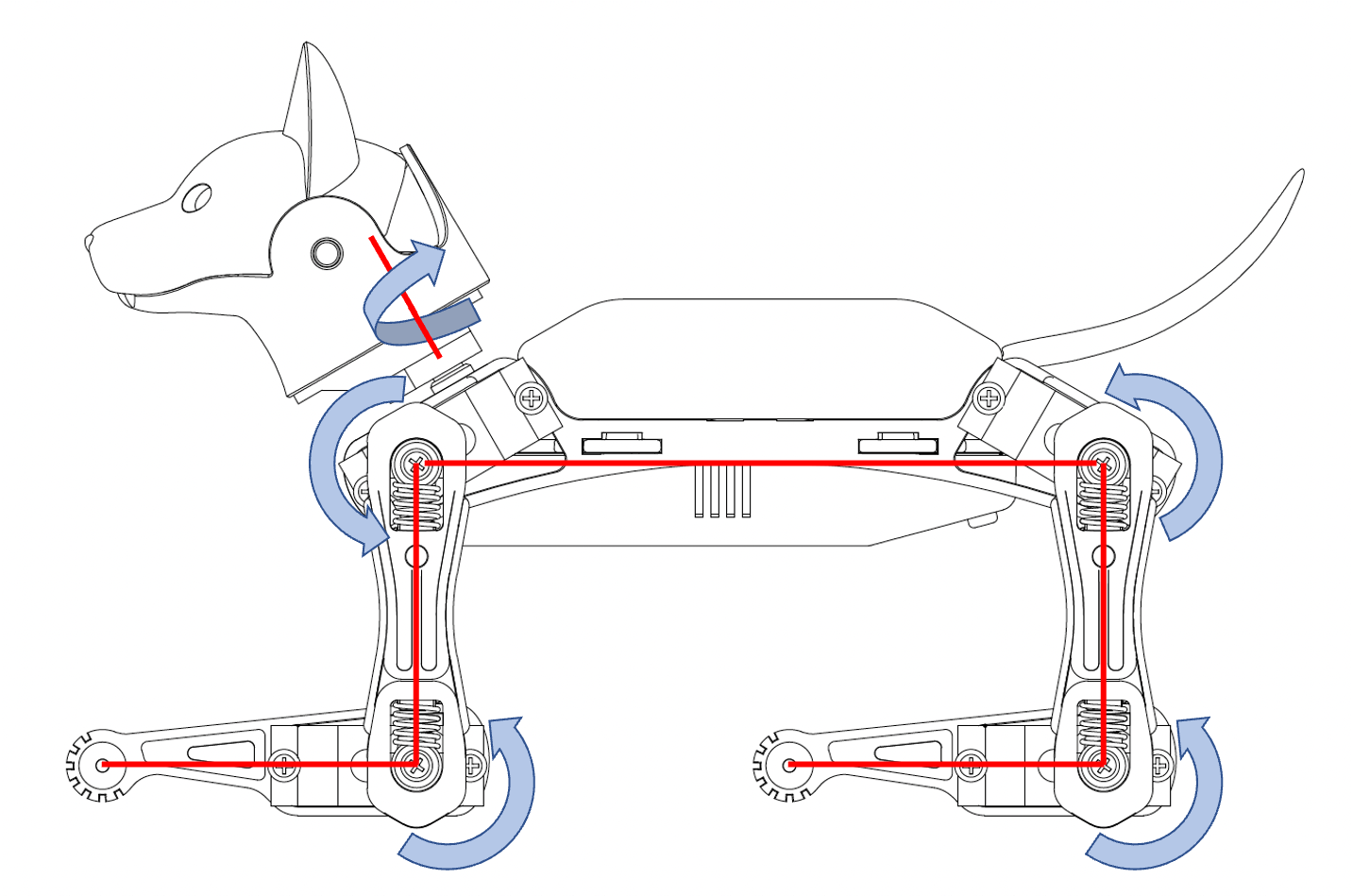

The rationale for calibration

Understand the zero state and the coordinate system

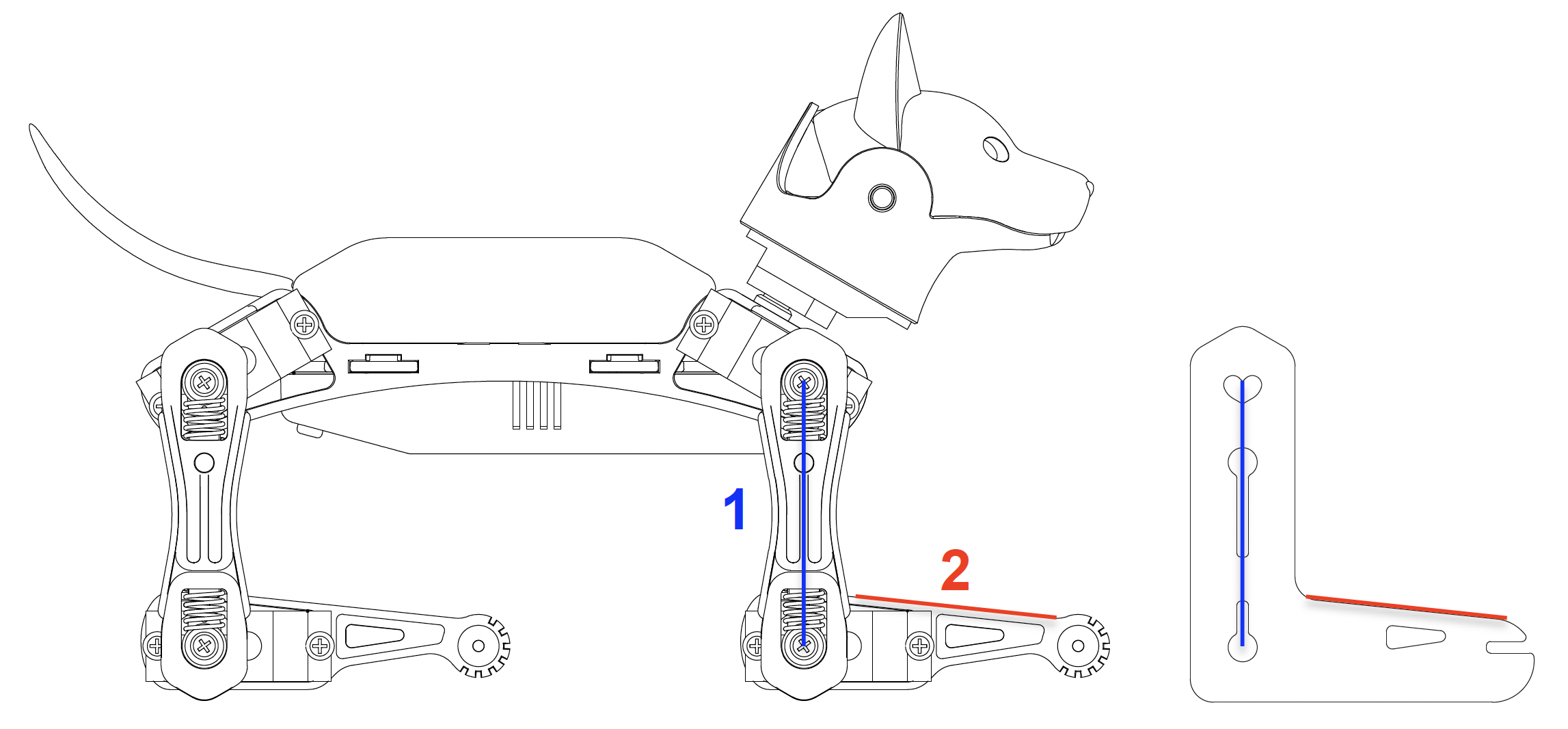

After entering the calibration state, with all servos rotated to their zero angles, attach the head, tail, and legs prepared in the previous section to the body. They are generally perpendicular to the body frames they are linked to. The calibration pose is shown below:

For the construction kit, please install the servo-related components as shown in the picture (calibration mode) and ensure they are perpendicular to each other (the upper leg is perpendicular to the torso, and the lower leg is perpendicular to the upper leg).

Note: Insert the servo-related components directly into the servo output shaft; do not turn the output shaft during this process.

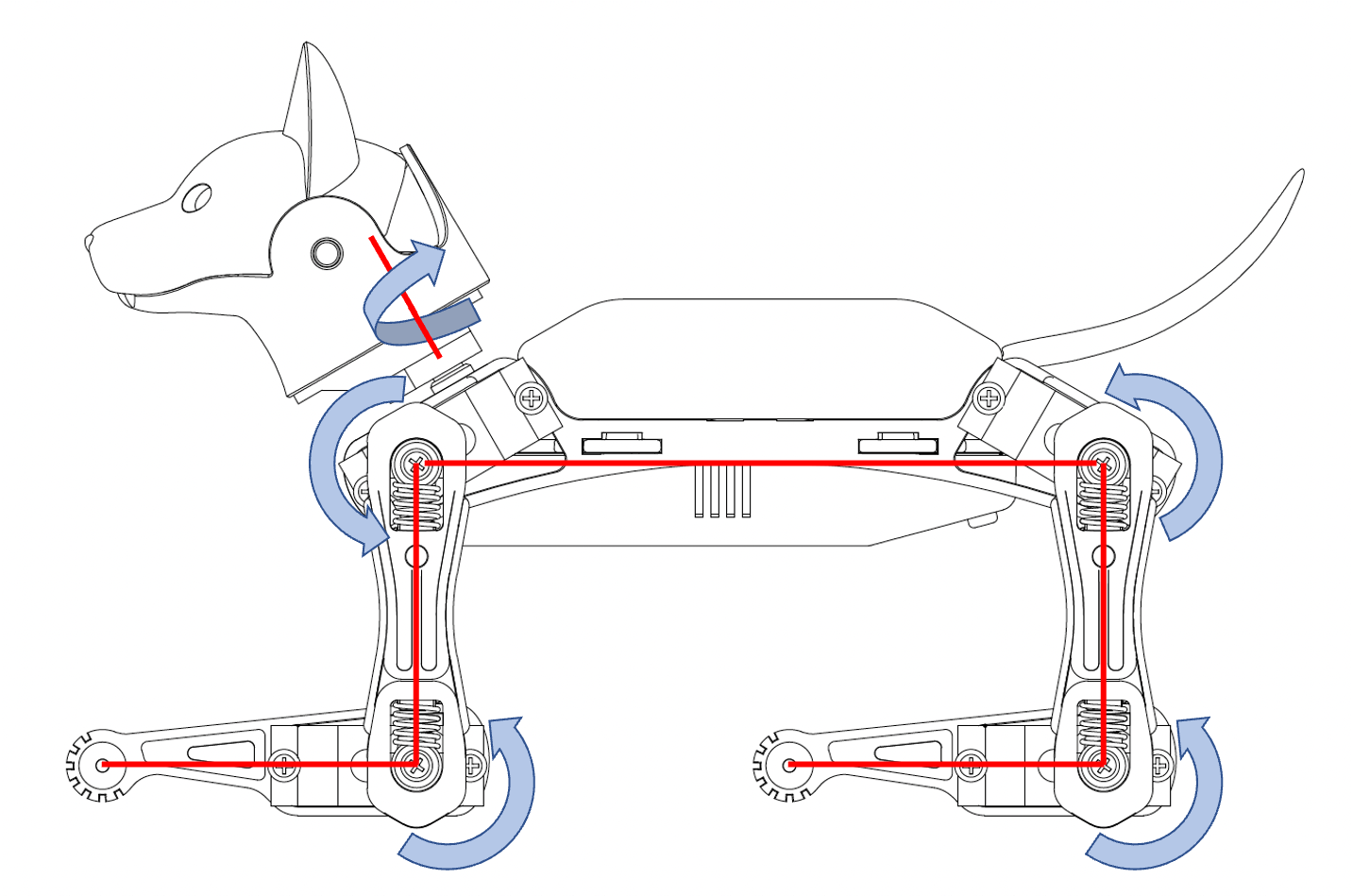

Rotating the limbs counterclockwise from their zero states will be positive (the same as in polar coordinates). Viewed from the left side of the robot's body, the counter-clockwise rotation of the joint is defined as the positive direction.

The only exception is the head tilt angle for Nybble. It’s more natural to say head up, while it’s the result of rotating clockwise.

However, from the right side of the robot's body, the rotation directions' positive and negative are just opposite.

Discrete angular intervals

If we look closer at the servo shaft, we can see it has a certain number of teeth. That’s for attaching the servo arms and avoiding sliding in the rotational direction. In our servo sample, the gears divide 360 degrees into 25 sectors, each taking 14.4 degrees(offset of -7.2~7.2 degrees). That means we cannot always get a perfect perpendicular installation.

Calibration process

Enter the calibration state

Connect the battery to the mainboard, then long-press the battery button for more than 3 seconds to power on the robot.

After a battery powers on the robot, there are two methods to enter the calibration mode:

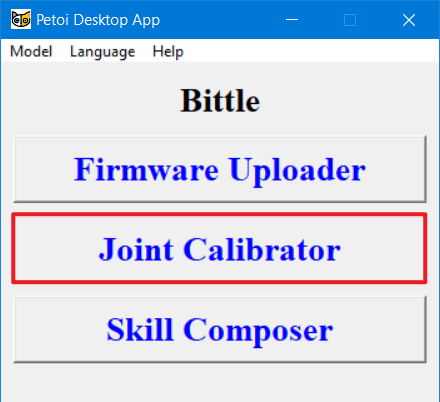

It will automatically enter calibration mode when you click the Joint Calibrator button.

Click the Calibrate button in the Joint Calibrator interface.

The servo slider is not available in the light yellow background area in the interface.

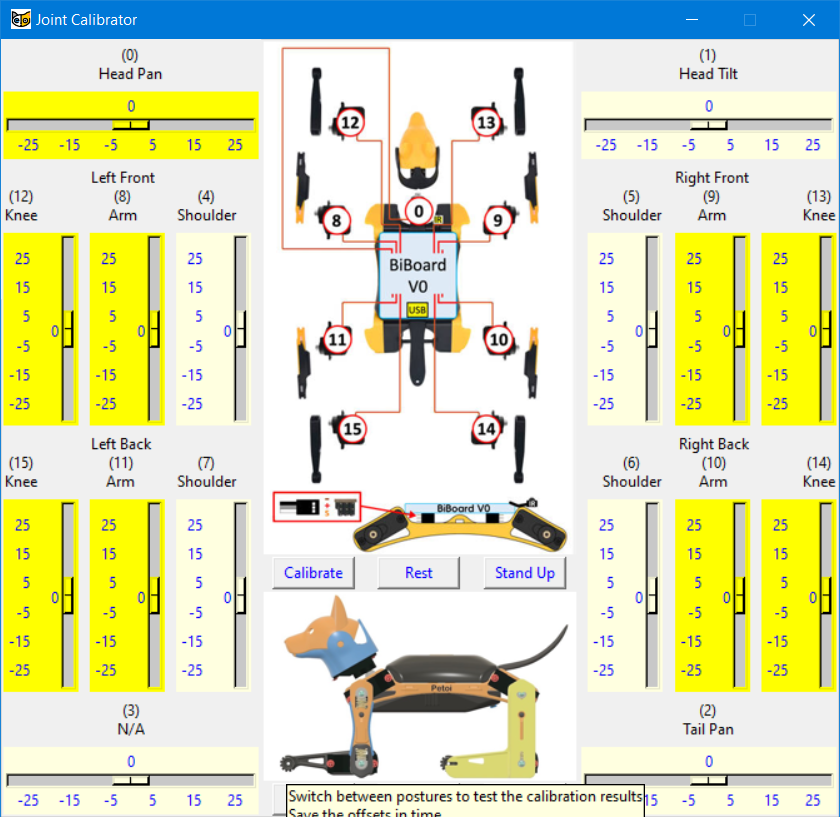

The joint calibration interface for Bittle X V2(BiBoard V1) in the Petoi Desktop App is as follows:

The joint calibration interface for Bittle X (BiBoard V0) in the Petoi Desktop App is as follows:

Installing and Fine-tuning

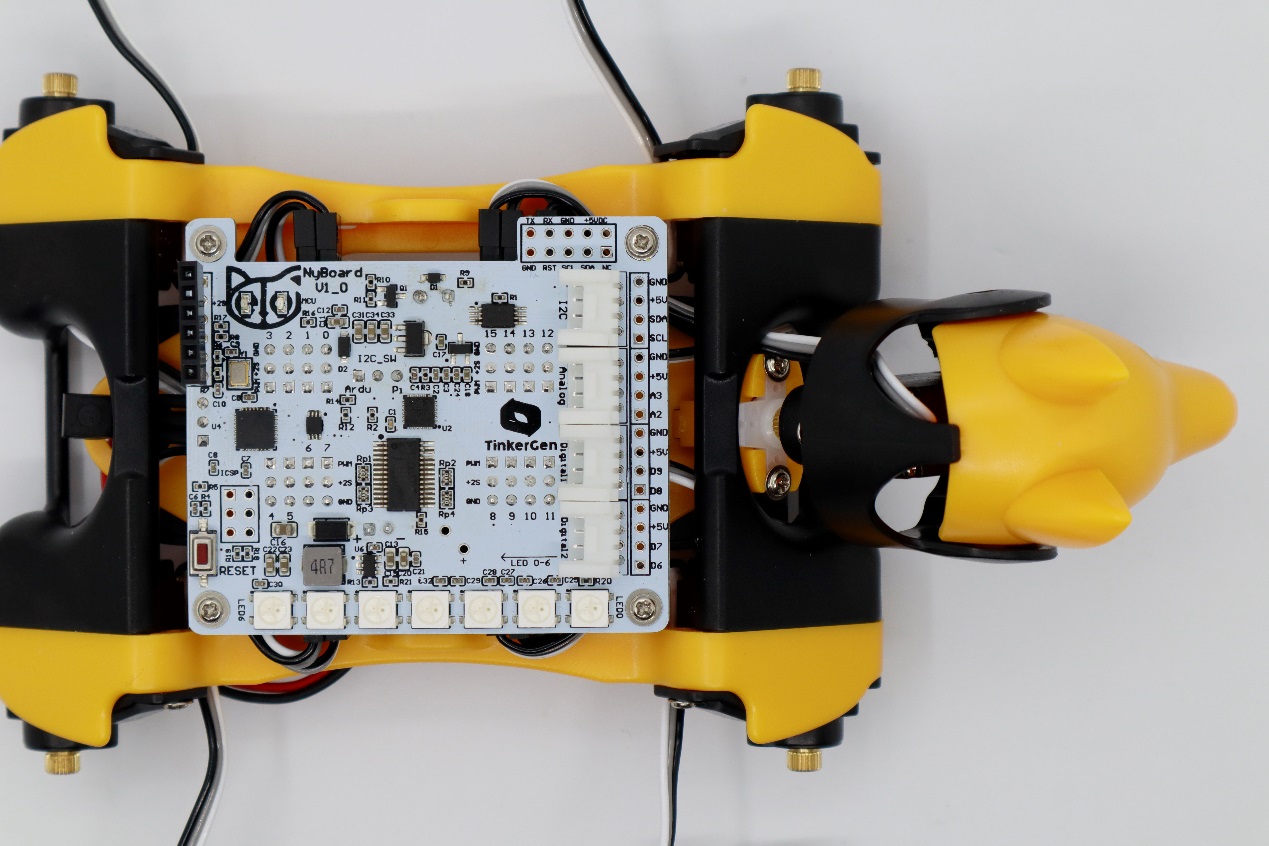

Please disregard the type of mainboard in the following installation pictures, as all Petoi mainboards have the same size.

For the Construction kit, after entering the calibration state, please install the neck servo and legs as follows:

Install the neck servo

In the calibration state, place the head as close to the central axis as possible and insert its servo shaft into the servo arm of the neck.

Press down on the head so it is firmly attached to the neck.

Install the legs

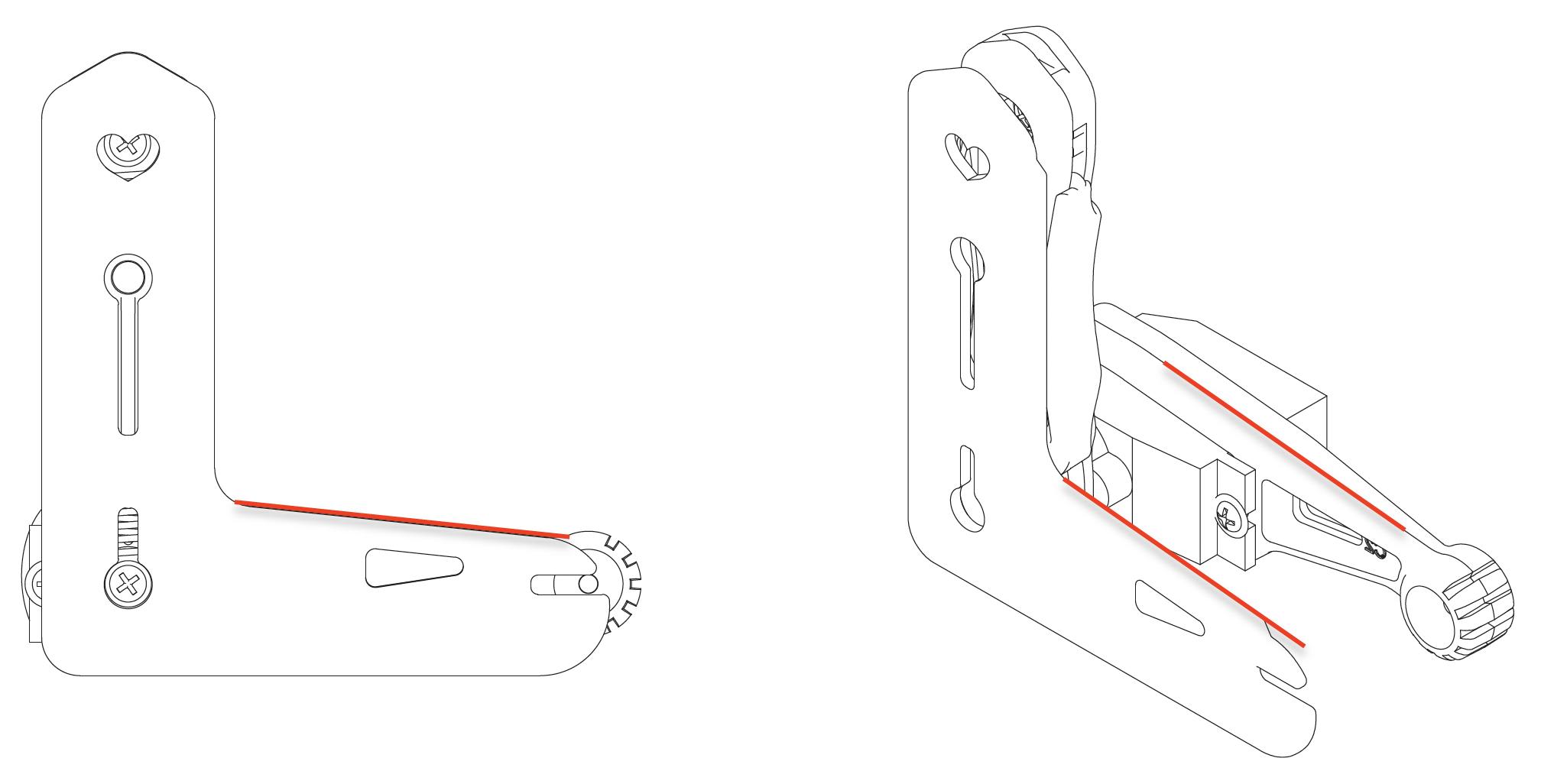

Install the upper leg and lower leg components to the output teeth of the servos after the Bittle is powered on and in the calibrated neutral position. Please keep the torso, upper leg, and lower leg installed vertically as much as possible. Do not install the lower leg backward, as shown in the picture.

Fine-tuning

The pre-assembled robot should already have the components adequately installed. You can do the joint calibration for fine-tuning directly, without needing to uninstall the head and legs.

Please use the L-shaped calibration tool included in the package as a calibration reference. According to the joint numbers shown in the calibration interface picture, click and drag the corresponding joint sliders or click the blank areas of the slider tracks to fine-tune the joints to a right angle.

Please note that when calibrating the servos, adjust the upper leg first, then change the lower leg.

If the offset is more than +/-9 degrees, you need to remove the corresponding leg and reinstall it by rotating one tooth and then dragging the corresponding slider. For example, when it is adjusted to +9 and still not right, remove the corresponding leg and shift one tooth when attaching it. Then, you should get a smaller offset in the opposite direction.

For the construction kit, please install the servo-related components as shown in the picture (calibration mode) and ensure they are perpendicular to each other (the upper leg is perpendicular to the torso, and the lower leg is perpendicular to the upper leg).

Note: Insert the servo-related components directly into the servo output shaft; do not turn the output shaft during this process.

Validation and Save data

You can switch between "Rest", "Stand up" and "Walk" to test the calibration effect.

If you want to continue calibrating, please click the Calibration button, and the robot will be in the calibration state again (all servos will move to the calibration position immediately).

Note: You may need a second round of calibrations to achieve optimal results.

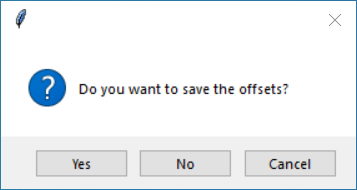

After calibration, remember to click the "Save" button to save the calibration offset. Otherwise, click the "Abort" button to abandon the calibration data. You can save the calibration in the middle in case your connection is interrupted.

When you close this window, there is a message box shown below:

To save the calibration data, please click the "Yes" button; otherwise, click the "No" button. Click the "Cancel" button to cancel or quit.

Install the screws for the construction kit

After completing the joint calibration, install the center screws to fix the components and servo gears.

Last updated