Calibrate the joints with Arduino IDE

Prepare to Enter the Calibration State

Please refer to the preparation section in the Joint Calibration.

The rationale for calibration

Understand the zero state and the coordinate system

After sending the serial command ‘c’ in the serial monitor, the robot will enter the calibration state, with all servos rotated to their zero angles, attach the head, tail, and legs prepared in the previous section to the body. They are generally perpendicular to their linked body frames.

Please refer to the subpage of Joint Calibrator for the calibration pose (Calibration State) according to the product type.

Rotating the limbs counterclockwise from their zero states will be positive (the same as in polar coordinates). Viewed from the left side of the robot's body, the counter-clockwise rotation of the joint is defined as the positive direction.

The only exception is the head tilt angle for Nybble. It’s more natural to say head up, while it’s the result of rotating clockwise.

However, from the right side of the robot's body, the rotation directions' positive and negative are just opposite.

Discrete angular intervals

If we look closer at the servo shaft, we can see it has a certain number of teeth. That’s for attaching the servo arms and avoiding sliding in the rotational direction. In our servo sample, the gears divide 360 degrees into 25 sectors, each taking 14.4 degrees(offset of -7.2~7.2 degrees). That means we cannot always get a perfect perpendicular installation.

Calibration process

Enter the calibration state

You must double-check the position and direction of all servos.

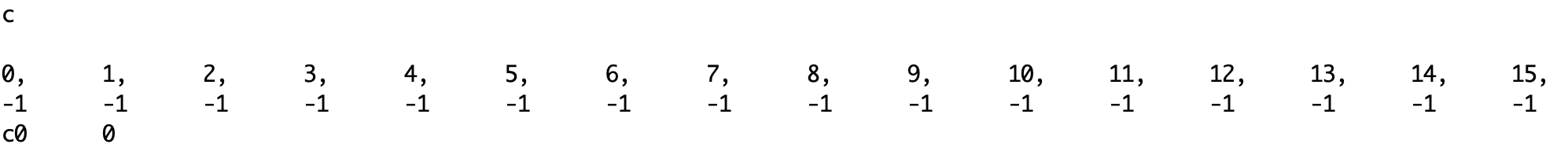

Send the serial command ‘c’ in the serial monitor to enter the calibration mode. Depending on their initial shaft direction, some may travel larger angles until stopping at the middle point. There will be noise coming from the gear system of the servos. You will see a calibration table like the following:

The first row is the joint indexes; the second row is their calibration offsets:

Index

0

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

Offset

-1

-1

-1

-1

-1

-1

-1

-1

-1

-1

-1

-1

-1

-1

-1

-1

Initial values are “-1” or “0” and should be changed by later calibration.

The servos use a potentiometer in the feedback loop for position control. When held at a static position, they tend to vibrate around the target angle. A Parkinson 's-like vibration will develop after a short period of use. It won’t affect much during continuous motion. Better servos without these troubles could cost 10 times more, so replacing a failed unit is a more cost-effective solution.

Attach body parts to the servos

For the installation for different product, please refer to the subpage of Joint Calibrator as above.

Fine-tune the calibration using the serial monitor

1. Joint Control Commands

The command for fine-tuning calibration (refer to the serial protocol) is formatted as cIndex Offset. Notice that there’s a space between cIndex and Offset.

For the index number of the robot's joints, please refer to the subpage of Petoi robot joint index as below:

For example :

c8 6This means giving the 8th servo an offset of 6 degrees.c0 -4This means giving the 0th servo(the head) an offset of -4 degrees.

The resolution of the correction amount is 1 degree; do not use decimals.

If you find the absolute value of offset is more significant than 9, you are not attaching the limb closest to its zero states. That will decrease the servo's reachable range on either side. Please take off the limb and rotate it by one tooth. It will result in an opposite but smaller offset.

For example, if you have to use -9 as the calibration value, remove the limb, rotate it by one tooth, and then attach it back. The new calibration value should be around 5, i.e., the sum of their absolute values is 14. Avoid rotating the servo shaft during this adjustment.

Find the best offset that can bring the limb to the zero states. It's a process of trial and error.

For the robotic arm, you can use the serial command "c-2" to auto-calibrate the robotic claw joint.

After calibration, remember to type ‘s’ to save the offsets. Otherwise, they will be forgotten when exiting the calibration state. You can even save every time after you’re done with one servo.

2. Use ‘L’ shaped joint tuner

When watching something, one's observations will change from different perspectives. When measuring length, one always wants to read directly above a referencing ruler.

You must keep a parallel perspective when calibrating the robot. Use the 'L'-shaped joint tuner as a parallel reference to avoid reading errors. Align the tips on the tuner with the center of the screws in the shoulder and knee joints and the little hole on the tip of the foot. Look along the co-axis of the centers. For each leg, calibrate the shoulder servos (index 8~11) first, then the knee servos(index 12~15). When calibrating the knee, use the matching triangle windows on both the tuner and shank to ensure parallel alignment.

For the ‘L’ shaped joint tuner of different products, please refer to the subpage of Joint Calibrator as above.

3. Testing and validation

After calibration, send the serial commands: ‘d’, ‘kup’, and 'kwkF' to validate the calibration. This will result in the robot symmetrically moving its limbs between the rest, stand states, and walk gait.

You may need to do a few rounds of calibrations to achieve optimal states.

Take Bittle, for example, as follows:

4. Install the screws for the construction kit

After completing the joint calibration, install the center screws to fix the components and servo gears.

5. Center of mass

Try to understand how the robot keeps its balance even during walking. If you add new components to the robot, distribute its weight symmetrically about the spine. You may also need to slide the battery holder back and forth to find the best balance spot. Because the battery is heavier at the front, you can insert it in the opposite direction to shift the center of mass farther back.

You may need to recalibrate if the center of mass changes.

Please do not force the robot to lift heavy objects, as this may cause the servos to sweep or get stuck.

Last updated