Bittle / Bittle X

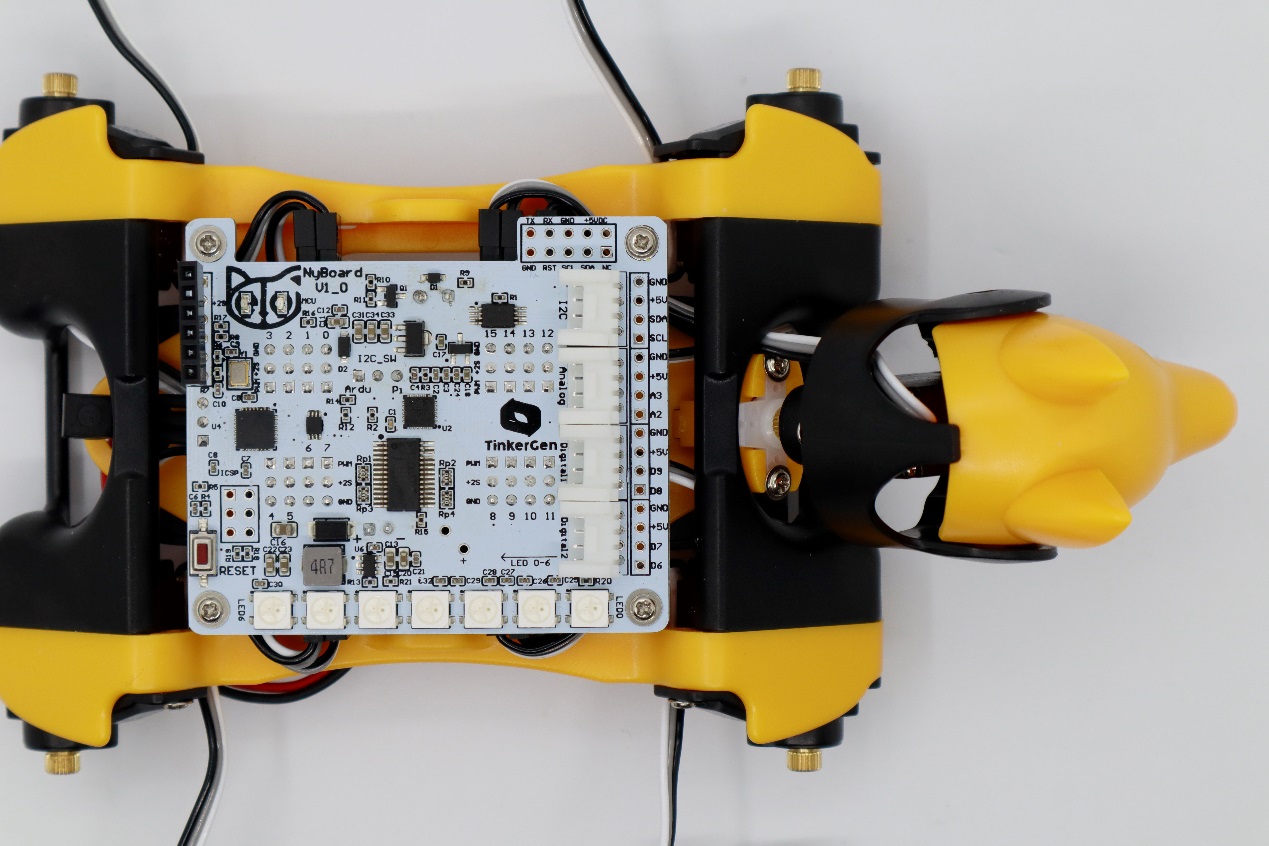

Bittle, Bittle X, and Bittle X+Arm use the same calibrator interface and process. You can ignore the mainboard type in the following pictures.

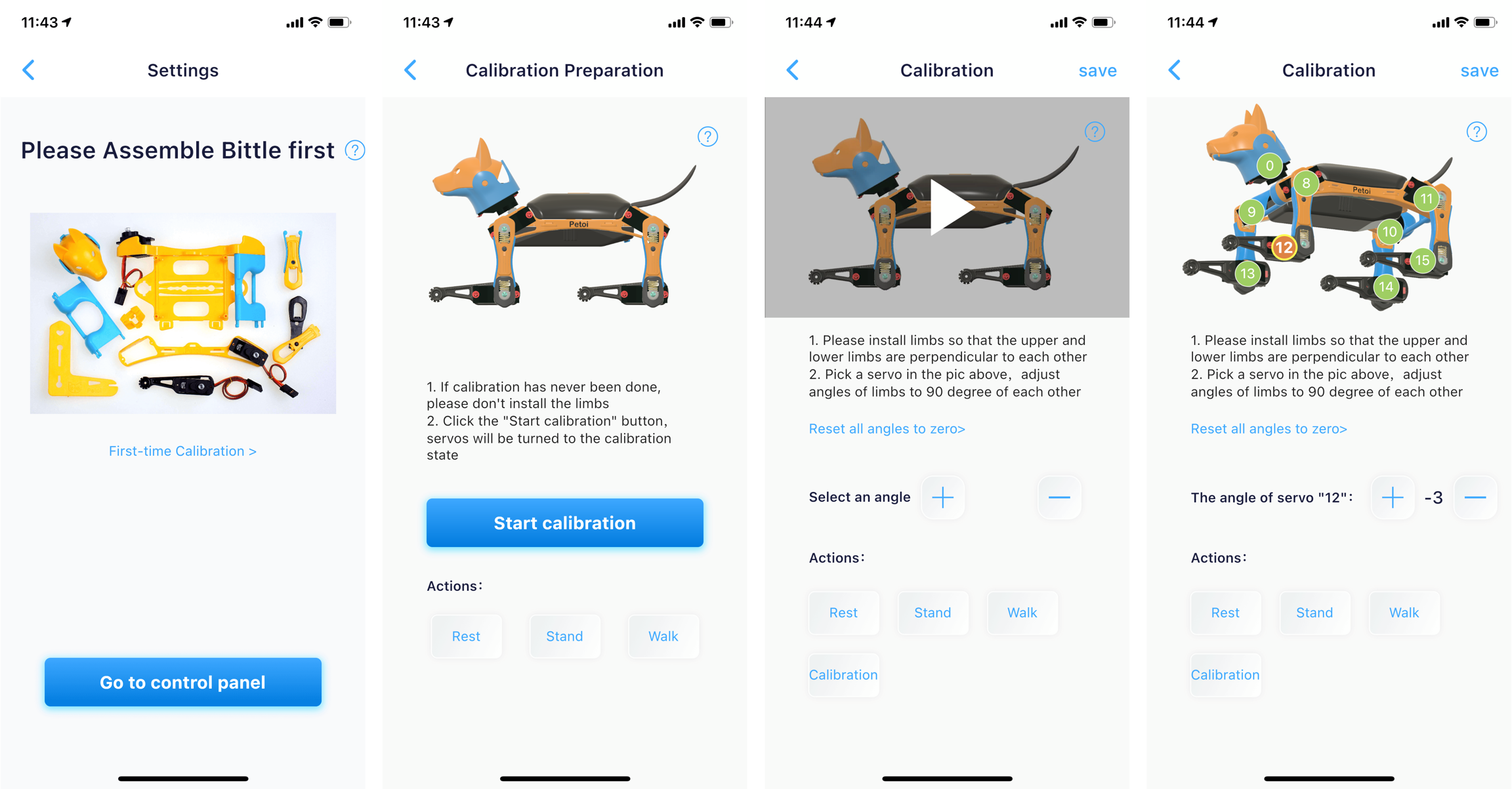

The calibrator interface for Bittle is as follows:

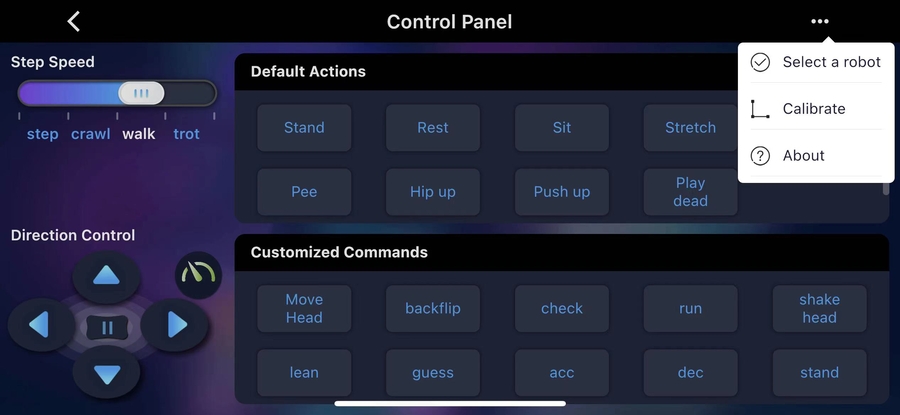

These interfaces will be displayed when you calibrate for the first time. You can also click to open the upper-right menu in the control panel and select Calibrate to re-access.

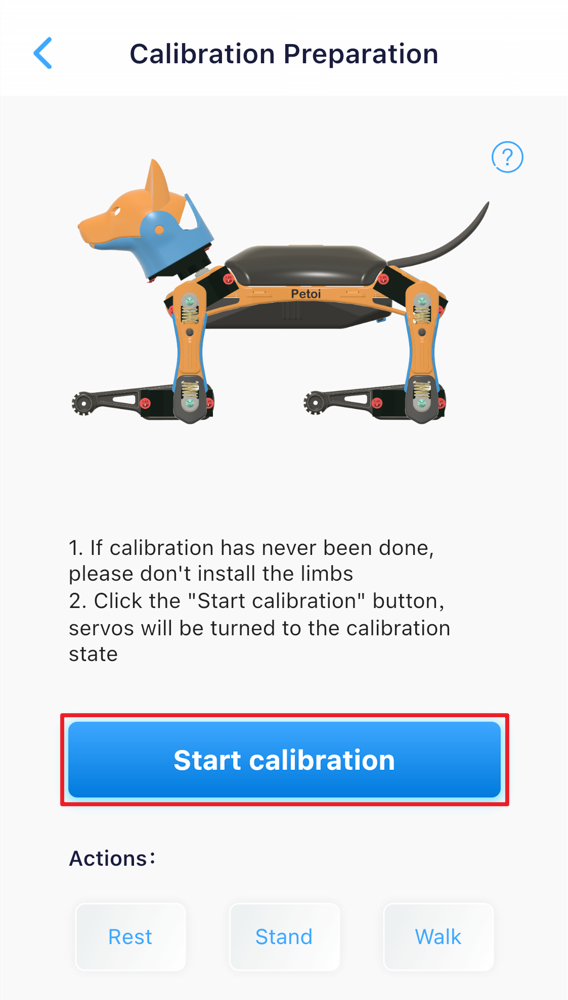

Enter the calibration state

After the battery powers on the robot, follow the next steps to enter the calibration mode.

Click the Start Calibration button.

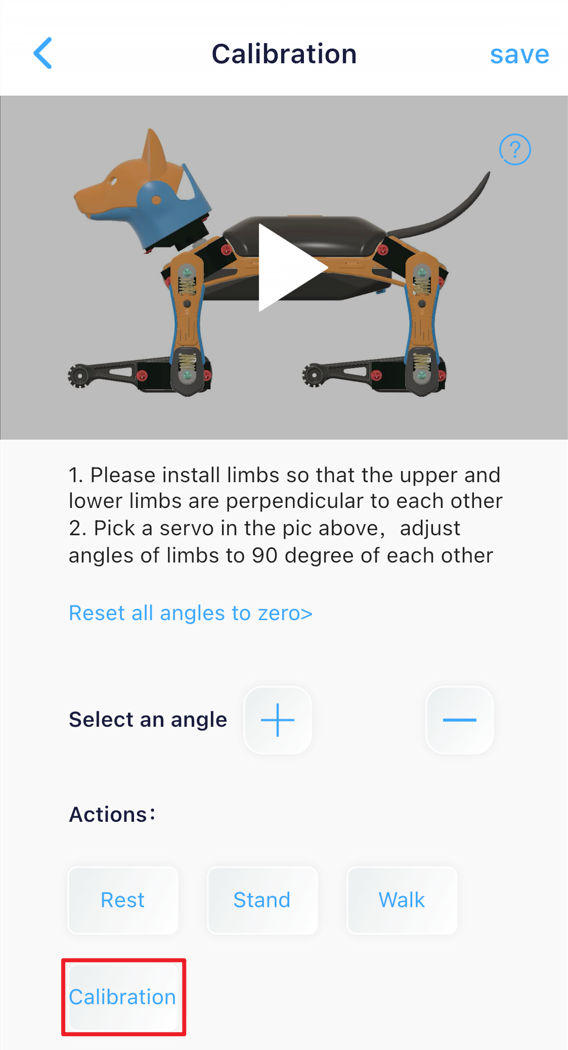

Click the Calibration button in the calibration interface.

After the robot enters the calibration mode, for the construction kit, do the following steps:

The pre-assembled robot has already had its joints calibrated, so there is no need to disassemble the joints for further calibration.

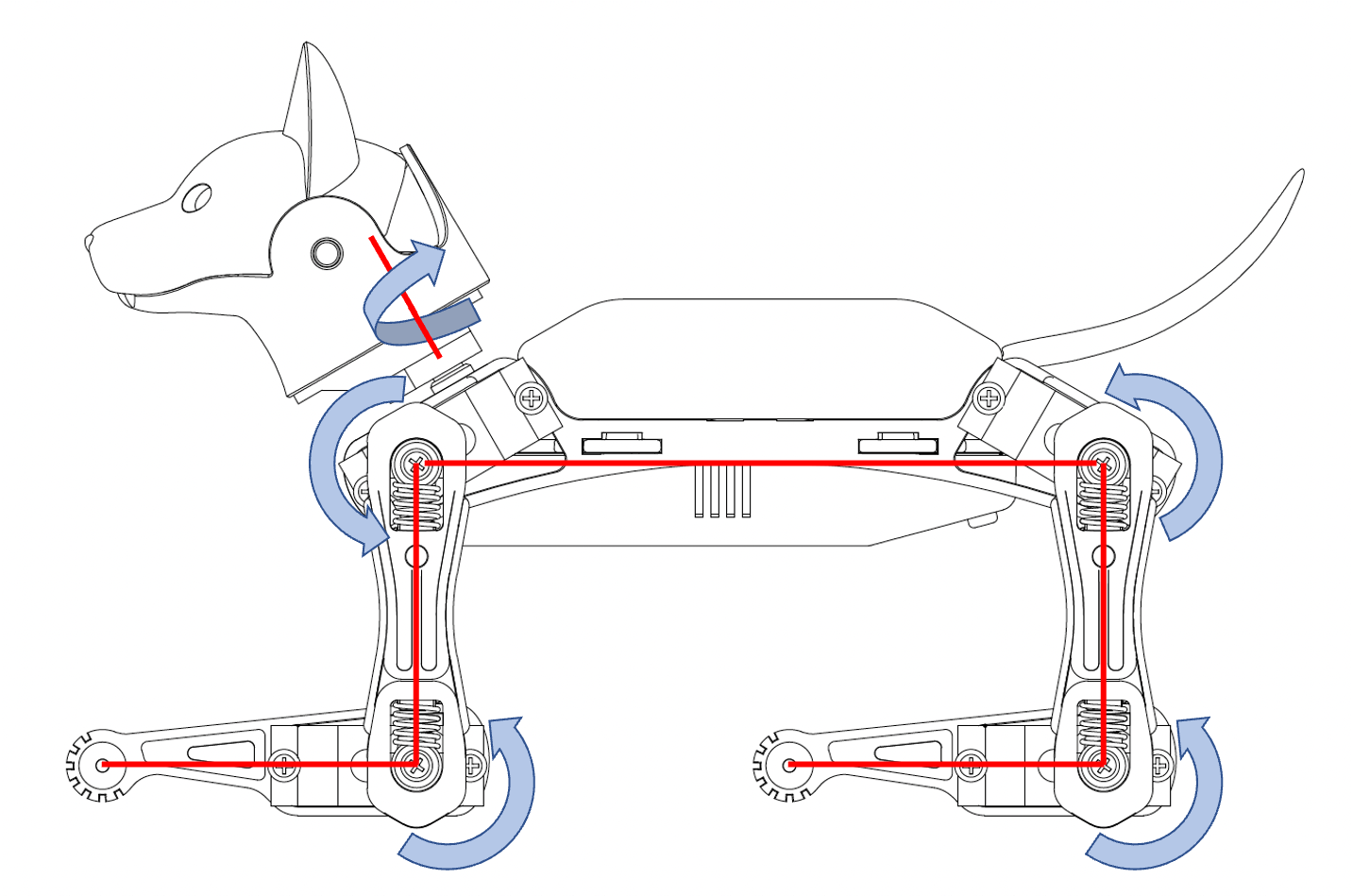

Bittle's calibration state

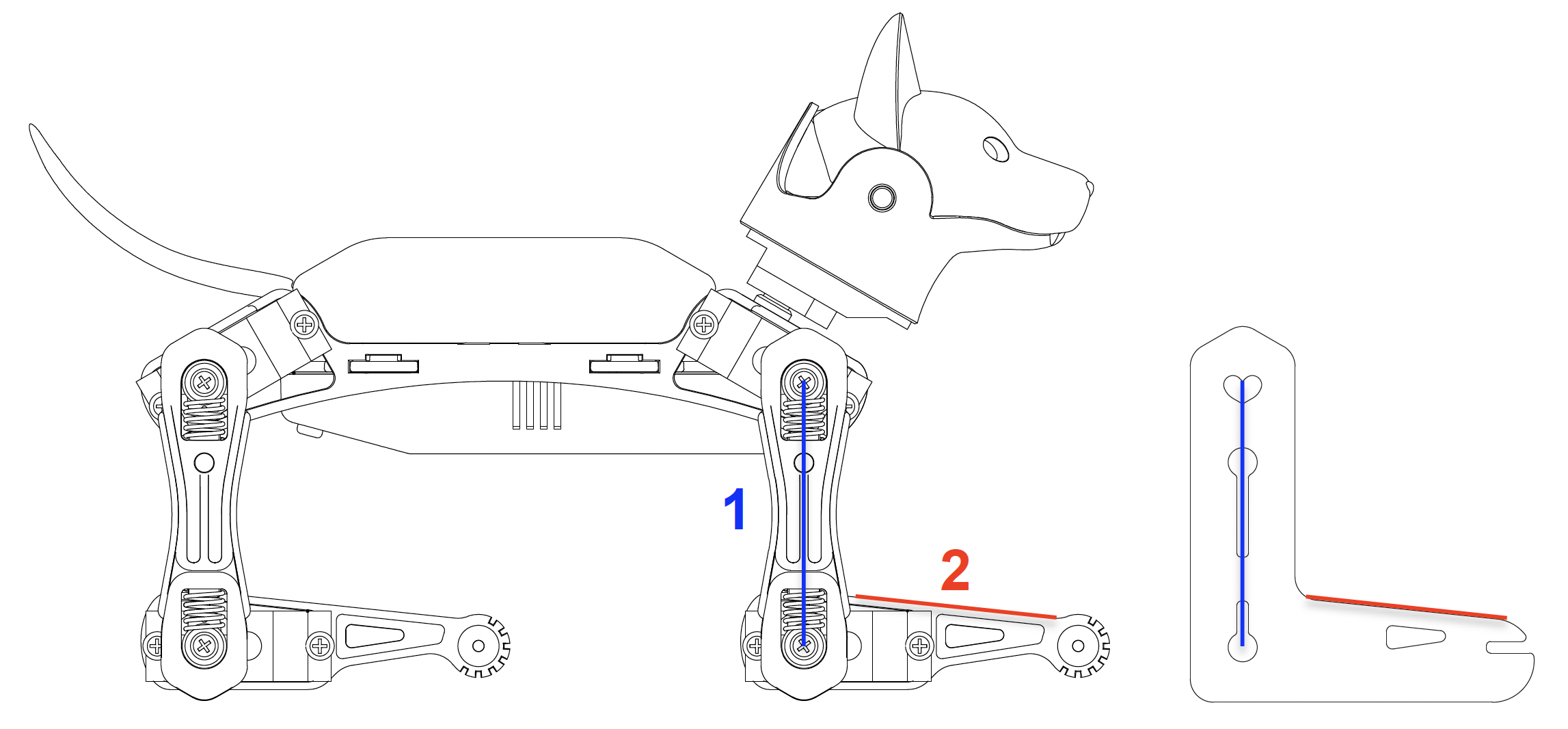

For the construction kit, please install the servo-related components as shown in the picture (calibration mode) and ensure they are perpendicular to each other (the upper leg is perpendicular to the torso, and the lower leg is perpendicular to the upper leg).

Note: Insert the servo-related components directly into the servo output shaft; do not turn the output shaft during this process.

Install the head

In the calibration mode, place the head as close to the central axis as possible and insert its servo shaft into the neck's servo arm.

Press down on the head so it is firmly attached to the neck.

Install the legs

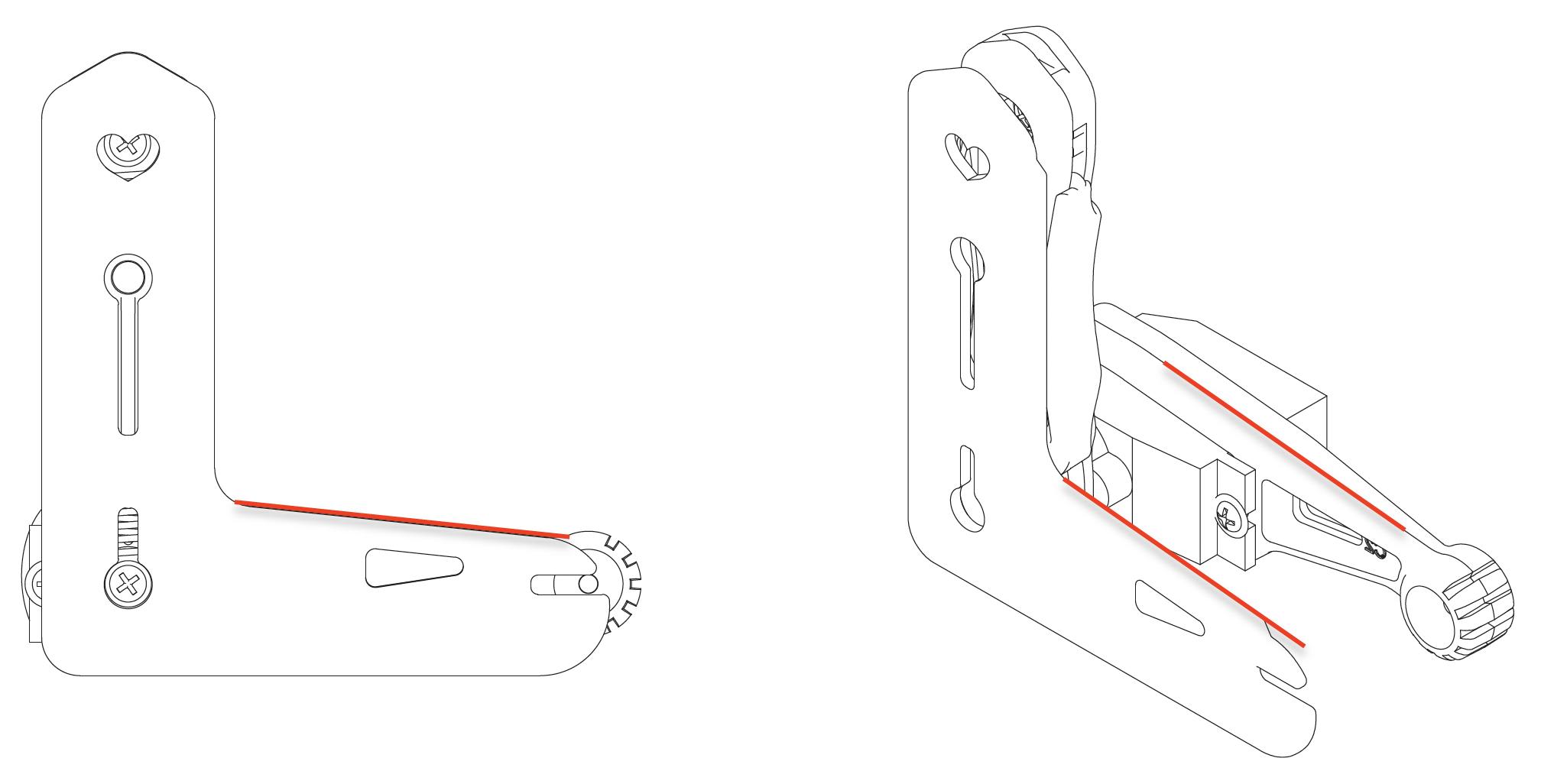

Install the upper leg and lower leg components to the output teeth of the servos when the Bittle is powered on and in the calibration mode. Please keep the torso, upper leg, and lower leg installed vertically as much as possible. Pay attention not to install the lower leg backward (the correct orientation is shown in the picture below).

Use the included L-shaped tool as a reference

First, select the index number of the joint servo from the diagram(when adjusting the leg servo, adjust the thigh first, and then adjust the calf).

Then, click the "+" or "-" button to fine-tune the joint to the desired angle.

If the offset is more than ±9 degrees, you need to remove the corresponding part of the servo, reinstall it by rotating one tooth, and then press the "+" or "-" button.

For example, if you need to use -10 as the calibration value, remove the limb, rotate it by one tooth, and then reattach it. The new calibration value should be around 4, i.e., they sum up to 14. Avoid rotating the servo shaft during this adjustment.

Last updated